One definition of the “American Dream” is “The belief that anyone, regardless of where they were born or what class they were born into, can attain their own version of success in a society in which upward mobility is possible for everyone. The American dream is believed to be achieved through sacrifice, risk-taking, and hard work, rather than by chance.” Wikipedia states, “The American Dream is rooted in the Declaration of Independence, which proclaims that “all men are created equal” with the right to “life, liberty and the pursuit of happiness.” The question is: Are we losing the “American Dream.?”

What the “American Dream” means to me is access to a good education, ability to have a good paying job, owning a home, and living in a safe, pleasant neighborhood. In other words, someone living the “American Dream” would be comfortably in the economic middle class in the United States. Let’s consider what has happened in the past 50 years.

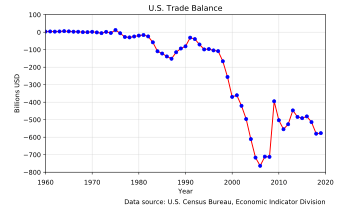

The chars below shows that the U. S. has been running a trade deficit since 1976. This means that we import more products than we sell. In 2020, the U.S. trade deficit was $678.7 billion, according to the U.S. Bureau of Economic Analysis (BEA), and more 42.1% of the U.S. trade deficit in goods is with China.

Trade deficits can occur for the following reasons:

- A country’s inability to produce some goods.

- Better quality of some foreign goods.

- Cheaper foreign materials.

- Lower foreign wages.

- Lower foreign capital costs.

- Subsidies from foreign governments to their manufacturers.

The last four reasons have been the main reasons for our trade deficit with China. China does not have a free-market economy; it is a controlled by the Chinese Communist Party, which uses mercantilist policies of product dumping, currency manipulation, intellectual property theft, and government subsidies to take over markets in the United states.

Higher Paying Jobs Disappearing

Trade deficits can result in a loss of up to 6,000 jobs for each one billion dollars of trade deficit. Since China joined the WTO in 2001, the US has lost 77,000 manufacturing establishments (factories), and nearly six million manufacturing jobs since the peak shown below in 1980.

| Percent Manufacturing Jobs in the U.S. | ||

| Year | Manufacturing Jobs (Millions) | Percent Manufacturing Jobs |

| 1976 | 17.8 Million | — |

| 1980 | 18.6 Million | 20.5 |

| 1990 | 17.3 Million | 16.1 |

| 2000 | 17.1 Million | 13.0 |

| 2010 | 11.5 Million | 8.9 |

| 2019 | 12.8 Million | 8.5 |

https://www.census.gov/foreign-trade/statistics/historical/index.html

Manufacturing jobs are the foundation of the middle class and as we lose manufacturing jobs, we are losing the middle class. As a result, median yearly wages have stagnated, only growing from $19,822 in 1985 to $51,916 in 2019, which is only a 1.21% average annual percent of change for a total 61% increase in 34 years, hardly enough to keep up with the annual rate of inflation.

In November 2019, the U.S. Private Sector Job Quality Index (JQI) began “to assesses job quality in the United States by measuring desirable higher-wage/higher-hour jobs versus lower-wage/lower-hour jobs… “job quality” means the weekly dollar-income a job generates for an employee.” The JQI White Paper states: “The size and composition of the U.S. labor force have changed substantially over the past quarter century…The percentage of private U.S. jobs in the service-providing sectors increased steadily from approximately 55% during the years immediately following the end of World War II through the end of the Great Recession in 2009. However, the percentage has remained flat—at around 83.5%— since that point.”

As a result of creating more lower paying service and retail jobs, the average hourly wage nationwide is $11.31/hour for a yearly average pay of $22,620 compared to the yearly average base pay of $47,945 ($23.97/hour) for a manufacturing job according to Glassdoor. However, a skilled automotive worker can make as much as $70,204 per year ($35.10/hour).

Another advantage of jobs in manufacturing is that they create more other support jobs that a retail job does. One the average, manufacturing jobs create 3 – 4 other indirect jobs, compared to less than one job for retail, but certain manufacturing jobs create more other jobs as shown below:

| Industry | Direct jobs | Total indirect jobs |

| Manufacturing | ||

| Steel product manufacturing from purchased steel | 1 | 12 |

| Motor vehicle manufacturing | 1 | 14 |

| Retail | ||

| Food and beverage stores | 1 | 0.7 |

| General merchandise stores | 1 | 0.7 |

The lack of growth in wages hasn’t been at the same rate for all income levels according to data from the Economic Policy Institute:

| Bottom 90% | Top 5% | Top 0.1% | |

| Net Growth in Wages 1979- 2019 | 26.0% | 75.1% | 345.2% |

Middle Class Shrinking

According to a Pew Research Center study, this stagnation of wages has caused a decrease in the percentage of Americans that are in the middle class. In 1970, 62% of Americans were in the middle class, but only 52% of Americans were in the middle class in 2018.

Home Ownership Stable

The good news is that home ownership nationwide has been relatively stable in the past 50 years, actually increasing from 64.0% in 1970 to 67.9% in the 1st quarter of 2020 according to data from FRED.

Why did we lose so many higher paying jobs?

I’ve written three books discussing this problem and what we can do about it, but in a nutshell, I can condense the reasons to the following major causes:

- Trade agreements such as NAFTA with Canada and Mexico (1994) that benefited our trading partners more than the U.S. and began the process of outsourcing jobs to other countries, primarily Mexico.

- Granting China Most Favored nation status in 2000 (now called Permanent Normal Trade Relations) and allowing them to become a member of the World Trade organization. This caused a mass exodus of manufacturing jobs from the U.S., either by outsourcing manufacturing to Chinese companies or American companies setting up manufacturing plants in China.

- Ending tariffs on imports from trading partners as part of the regulations of the World Trade Organization Agreement.

- Tax policies that favor multinational global corporations, allowing them to shift profits to other countries and encouraging them to outsource manufacturing jobs.

How can we create more higher paying jobs to restore the American Dream?

Since it took us nearly 30 years to get to this point, there is no simple, rapid solution. However, there are steps our government has taken and can take to accelerate restoring the American Dream:

- Renegotiate existing trade agreements to require trading partner countries to purchase more U. S. agricultural products and energy products such as oil, gas, and renewables.

- Maintain current tariffs and expand tariffs to other critical, essential products

- Pass Sales Factor Tax Apportionment legislation, which would require multinational corporations to pay taxes on the profits of their sales in the U.S., discouraging profit shifting.

- Pass Market Access Charge legislation to tax foreign entities and individual on purchase of U.S. assets; i.e., stocks, bonds, companies, and property, which would gradually balance the overvalued dollar.

These recommended policy steps have been described in more detail in past blog articles available to read at www.savingusmanufacturing.com. And, these policies were discussed at the annual trade conference held virtually on March 23-26, 2021 by the Coalition for a Prosperous America, about which I will be writing in future articles.