Recently, I had the pleasure of connecting with Rita Crompton, known as America’s Inventor Lady after a referral from a mutual friend who thought we had common interests because of my being involved with the San Diego Inventors Forum for about 15 years.

I asked if she had ever invented anything herself, and she said she hasn’t. I told her I hadn’t invented anything for which I had received a patent although I had developed ideas for produces in the past. She said that she got that moniker because of her work in helping inventors get their ideas out of their heads and into the marketplace (from “mind to market”, as she says), as well as helping them get licensing agreements once their ideas are ready for the markets. She’s plied her trade in this fashion for more than the past 20 years. I told her that I use my expertise in manufacturing to help guide inventors on how to select the right manufacturing processes and sources.

Prior to her work with inventors, she published murder mysteries, tutored middle school and high school students, and continued in volunteer capacities with various charities and professional associations with which she was affiliated.

While she lived in Chicago for many years, she also spent time in Tulsa, Oklahoma, Marietta, Georgia, Denver, Colorado and, now, her current residence, in Eastern Tennessee.

When she moved to Denver, as a Gold Star member of the Denver Chamber of Commerce she encountered professional inventors, including three “ex-rocket scientists,” one of whom, Warren Roh, became her a mentor and trained her in the art of first finding, and successfully consummating licensing deals for inventor clients.

In February of 2006, she and Warren Roh started The Inventors’ Roundtable™, an inventing roundtable forum which nurtured a large network of inventors in Colorado’s Front Range. One of the main complaints the older inventors had of the local group was the cost to be a member and the overload of service providers. Rita promised the three older inventors who helped start the Inventors Roundtable 17 years ago that it would always be free and service providers would be by invitation only and that is still true.

After her recent relocation to Del Rio, Tennessee, and the Covid Pandemic, the IRT meetings changed to virtual meetings. This allows the IRT to serve any inventor (rural, city or suburb) from the comfort of their home to join in, ask questions and share successes and challenges with each other. The 2nd Thursday of the month is the IRT Virtual West and the 4th Monday of the month is the IRT Virtual East. However, anyone from anywhere can join the meeting via the posted link.

She explained. “The Inventors’ Roundtable is, and has always been, a free, safe environment where inventors learn about the invention process, how to protect their invention and how to get their idea to market. Service providers, by invitation only, donate their time to the inventors once a month. In addition, experienced and successful inventors mentor those just getting started learning the inventing process.”

She also spoke about her own company, FLeCusa International. “I started FLeCusa in 2007 to help the little guy, the solo and newbie inventors”, she told me. She said “I did it to provide a unique service to those clients, almost all of whom are without the resources available to a large corporation, but many of whom nevertheless wish to enter the marketplace or grow their business to a new level, both nationally or internationally. “In that sense, I’m kind of the inventor’s advocate, assisting to help level the playing field between them and larger, more resource-rich companies.”

She added, “My goal is to bring the corporate environment resources to the individual inventor. I help inventors understand the inventing process, bring their invention to market, establish distribution networks, protect their intellectual property and treat their invention like a business. My husband is my partner and he works with me in the business using his skill sets as both a transactional attorney (i.e., to prepare contracts) and part-time webmaster, using his experience with social media to manage my internet outreach and to drive traffic to my websites. In the end, I am the inventor’s advocate to help level the playing field.

As a licensing agent, Rita gets paid when the inventor gets paid. There is no up-front fee because she can’t promise a deal any better than other licensing company. Rita generally focuses on consumer products. However, she will work in Home Health Care and with environmental safety products. “Last year a young woman who had Early Onset Parkinson and had a feeding tube through high school and college. That feeding tube caused a horrible rash on the skin. This was a huge problem for anyone needing a feeding tube to survive. The inventor went to college, became a chemist, and proceeded to invent a solution to her problem. Within a few weeks of filing the patent using one of registered patent attorneys I know, we licensed the new product to the company that makes the feeding tubes. They had known about the problem for decades but never had a solution. The product is now sold worldwide.”

Rita wrote the Inventors Galaxy Guide, which she updates regularly. The 2025 edition is ready this week. It can be downloaded for free by subscribing to the Invent America Newsletter at www.AmericasInventorLady.com. This tool is a simple guide to help inventors understand the steps of the inventing process and the parameters for the costs at each stage.

In March of 2024, Rita, her daughter, Kat, and her husband started going to the shows produced by ASD Market Week (Affordable Shopping Destination), which are held in March in Las Vegas, NV. ASD Market Week is the largest wholesale retail merchandise show in the U.S. They take up to 25 inventors with them to the show each year. “ASD Market Week was amazing this year. We had one inventor with an athletic training tool. We had no idea that an NFL licensing agent would be at the show with his own invention wanting to join us. He now has three of our ASD products for his team to consider. You just never know who will be at a show and take your product to the next level”

I asked her how she got to have a radio show. She said, “The HomeTalk USA radio has been on coast-to-coast radio program for more than 25 years. It is the longest running DIY radio talk show in history. Invent America Radio has been part of it for two and a half years, and ASD Market Week is one of the sponsors of our show. It is free for inventors to be on the show, so if any inventors are interested, they can email her at rita@americasinventorlady.com.”

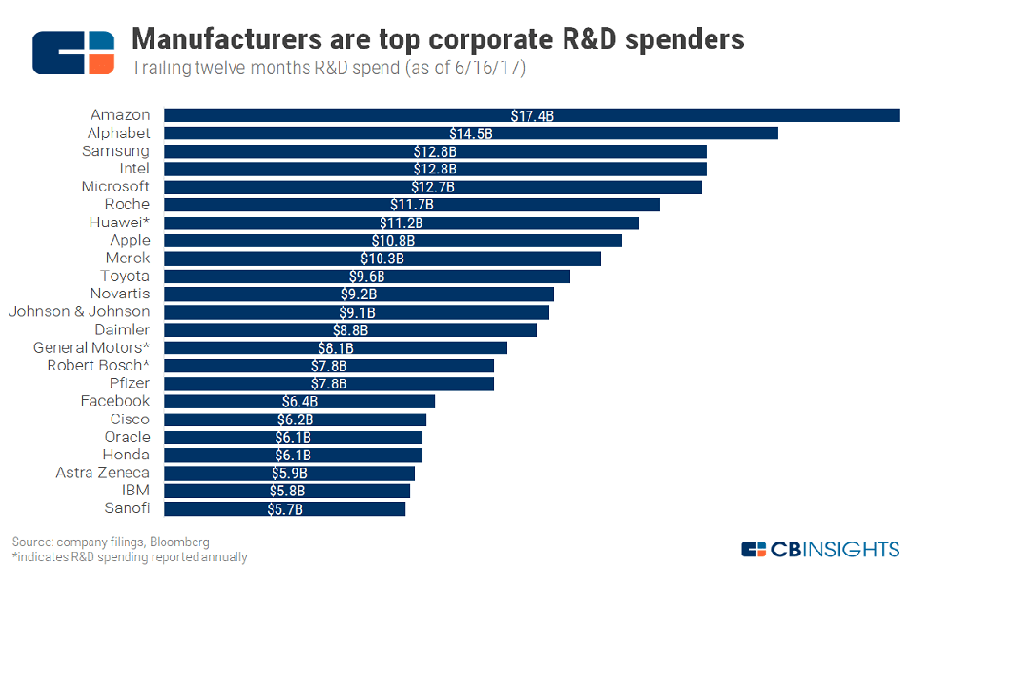

She mentioned that at this month’s Inventor’s Roundtable meeting, the speaker is a counselor on the R&D tax credit, who will discuss how an inventor can get a R & D tax credit after the inventor starts making money on his product. The R&D tax credit can go back three years. Join her for the upcoming Inventors Roundtable Meeting (it’s free!) and learn how to let the U.S. Government help you take advantage of the new R&D tax credit to recover some of the cost of getting your idea up and running.

In conclusion, we agreed that the best help inventors could get now would be to have Congress pass a Patent Reform Bill that would restore inventors’ rights and end abuses by the Patent Trial and Appeal Board (PTAB). Hopefully, Rep. Thomas Massie (R-KY) and Rep. Marcy Kaptur (D-OH) will reintroduce HR 8134, the Restoring America’s Leadership in Innovation Act (RALIA) that didn’t get out of committee last year to be voted on by the whole of Congress.