Many people think that the decline in American manufacturing started with American manufacturers sourcing manufacturing offshore in order to achieve lower labor costs, avoid regulations, and pay lower taxes. While the decline accelerated after China was granted the status of Permanent Normal Trade Relations (PNTR) and was allowed to join the World Trade Organization, it actually began decades earlier.

PNTR is a legal designation in the U. S. for free trade with a foreign nation and was called Most-Favored-Nation (MFN) until the name was changed in 1998. Thefreedictionary.com defines it as “A method of establishing equality of trading opportunity among states by guaranteeing that if one country is given better trade terms by another, then all other states must get the same terms.”

Thus, it is a method to prevent discriminatory treatment among members of an international trading organization. It provides trade equality among trading partners by ensuring that an importing country will not discriminate against another country’s goods in favor of those from a third. Once a country grants any type of concession to a third-party country, this concession must be given to all other countries.

At the end of World War II, the United States was the dominant manufacturing country of the world. The American manufacturing base had enabled the U. S. to win the war with Germany and Japan by outproducing these two countries in implements of war from ships to tanks to weapons.

Over the next 20 years, American manufacturing became synonymous with quality and inventiveness. Companies like Ford, General Motors, General Electric, Hewlett Packard, and Levi Straus became household names.

One of the main reasons why the United States became the dominant manufacturing country in the world was that for over 150 years, our government protected and fostered the growth of American industry through tariffs. The first tariff law passed by the Congress, was the Tariff of 1789. The purpose was to generate revenue to fund the federal government, pay down the debt of the government, and also act as a protective barrier for domestic industries from imports from England and France in particular.

Tariffs played a key role in our country’s foreign trade policy and were the main source of revenue for the federal government from 1789 to 1914, the year after income taxes went into effect in 1913. During this long period of time, tariffs averaged about 20% on foreign imports, and at times, tariff revenue approached 95% of federal revenue.

During the Truman Administration (1945-52), foreign trade policies began to focus on liberalizing trade through moving from protective tariffs to free trade. The instructions given from Congress to the U. S. Trade Representative were: Remove barriers to trade. A key concept of the liberalization of trade was reciprocal tariffs and low tariff rates. Two of the main reasons for this change in trade policy were to help Europe and Japan rebuild after the war and engender closer relations with the U. S. as a deterrent to the spread of communism. This ended the use of tariffs as a significant source of Federal revenue and began the increase of corporate and personal income taxes.

In 1948, the General Agreement on Tariffs and Trade (GATT) treaty “was signed by 23 nations in Geneva on October 30, 1947, and took effect on January 1, 1948. It remained in effect until the signature by 123 nations in Marrakesh on April 14, 1994, of the Uruguay Round Agreements, which established the World Trade Organization (WTO) on January 1, 1995. The WTO is in some ways a successor to GATT, and the original GATT text (GATT 1947) is still in effect under the WTO framework, subject to the modifications of GATT 1994. GATT, and its successor WTO, have successfully reduced tariffs. The average tariff levels for the major GATT participants were about 22% in 1947, but were 5% after the Uruguay Round in 1999.”

GATT requires that exports of all countries that are party to the treaty should be treated alike by other countries that are party to the treaty, and each member is granted Most Favored Nation status. Since GATT was first signed, MFN (now PNTR) status has been granted to about 180 countries. Only a handful of communist countries have been denied MFN status.

For over 20 years, American manufacturers experienced little competition from foreign exports, but in the 1970’s Japanese and German products began to significantly penetrate the U. S. market. Due to the focus on demilitarization and decentralization in the U. S.- directed rebuilding of the Japanese and German economies, producing consumers goods was the focus.

Japan focused on audio/stereo products, cameras, pianos/keyboards, and TVs, as well as low cost automobiles and motorcycles. Companies such as Panasonic, Sony, Sanyo, Yamaha, Toyota, Mitsubishi, and Datsun (now Nissan) became the new household names in America. Mitsubishi had produced aircraft in Japan before and during WWII, including the infamous fighter plane, the Zero. Nakajima was another aircraft manufacturer that was reformed as Fuji Heavy Industries after the war and began to produce the Subaru vehicles.

Germany started focusing on automobiles such as the Volkswagen “Bug” and bus, BMWs, and then Mercedes vehicles. They expanded into manufacturing equipment, machine tools, and scientific and laboratory instruments and equipment. Volkswagen was instrumental in Germany’s industrial recovery as their plants have escaped damage from bombing. The Volkswagen plant had been offered to England after the war as reparations, but England turned it down. Without Volkswagen being able to start manufacturing autos in 1946 after the war, the reindustrialization of Germany would have been delayed considerably.

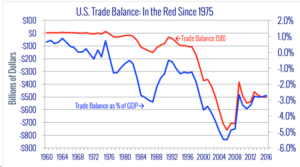

It didn’t take long for the increased imports from Japan and Germanys to take their toll on the U. S. trade balance. As the below chart shows, the last year we had a positive trade balance in goods was 1975:

Source: Coalition for a Prosperous America

Source: Coalition for a Prosperous America

As a developing country, imports from China didn’t become a significant factor until the beginning of the 21st Century. The development and growth of China’s manufacturing industry was essentially funded through American companies setting up manufacturing plants in China starting in the 1990s and transferring manufacturing to Chinese contract manufacturers. Foxconn, Apple’s contract manufacturer for the iPhone and iPad, is the only Chinese manufacturer to become well known in the U.S. While Foxconn has plants in mainland China, it is actually owned by Hon Hai Precision Industry Co., Ltd., a Taiwanese multinational electronics contract manufacturing company headquartered in Tucheng, New Taipei, Taiwan.

“In article titled “The Death of American Manufacturing,” published in the February 2006 Trumpet Print Edition, Robert Morley wrote: “Manufacturing loss is occurring because of globalization and outsourcing. Globalization is the increased mobility of goods, services, labor, technology and capital throughout the world; outsourcing is the performance of a production activity in another country that was previously done by a domestic firm or plant.

At the dawn of globalization, the elimination of trade barriers opened up access to foreign markets for American manufacturers in return for building factories abroad. In due course, more and more manufacturers set up shop overseas, producing goods to be sold to Americans.”

According to Yashen Huang author of Capitalism with Chinese Characteristics, China’s “indigenous private sector is conspicuously small.” The majority of urban companies are still State-Owned Enterprises (SOE’s). Other companies are privately owned, but the owner(s) are government employees, so they are still essentially government controlled.

China had lost its status as MFN through suspension in 1951 after the Communists took over control of the government in 1949. It was “restored in 1980 and was continued in effect through subsequent annual Presidential extensions. Following the massacre of pro-democracy demonstrators in Tiananmen Square in 1989, the annual renewal of China’s MFN status became a source of considerable debate in the Congress…Congress agreed to permanent normal trade relations (PNTR) status in P.L. 106-286, President Clinton signed into law on October 10, 2000. PNTR paved the way for China’s accession to the WTO in December 2000…;”

- S. trade with China began to be measured in 1985 by the U. S. Census Bureau, and we had only a small deficit of $6 million. The trade deficit grew to $83.8 billion by the year 2000. However, after China was granted PNTR and became a member of the WTO, the trade deficit started to escalate. It doubled to $162.3 in 2002 and doubled again by 2014 to $344.8 billion. The 2016 trade deficit was $347 billion, down from $367 billion in 2015. In 2016, China represented 38% of our overall trade deficit of $654.5 billion.

As a result of the escalated trade deficits from 2001 to 2010, the U.S. lost 5.8 million manufacturing jobs and 57,000 manufacturing firms closed. Where do all the jobs go? Well, the U.S. Department of Commerce shows that “U.S. multinational corporations… cut their work forces in the U.S. by 2.9 million during the 2000s while increasing employment overseas by 2.4 million.” So, we lost about half to offshoring of manufacturing to China and other parts of Asia.

The real story is even worse than this data. In an article by Terence P. Jeffrey published on www.CBSNews.com on May 12, 2015, “The number of jobs in manufacturing has declined by 7,231,000–or 37 percent–since employment in manufacturing peaked in the United States in 1979, according to data published by the Bureau of Labor Statistics.

As a result of more and more American manufacturers setting up plants in China, our domestic supply chain was weakened. From 2001 to 2010: The U. S. textile industry lost 63% of jobs since 2001. Communication equipment industry lost 47% of its jobs. Motor vehicles and parts industry lost 43% of its jobs. U. S. machine tool industry consumption fell 78% in 2008 and another 60% in 2009. U. S. printed circuit board industry has shrunk by 74% since 2000. We even lost whole industries, such as: fabless chips, compact fluorescent lighting, LCDs for monitors, TVs and handheld devices like mobile phones displays, Lithium ion, lithium polymer and NiMH batteries, low-end servers, hard-disk drives, and many others.

After over 40 years of trade policies that foster offshoring, it’s time to have a new goal for trade policies. Instead of “remove barriers to trade,” we need to have a goal of “eliminating the trade deficit.” The Coalition for a Prosperous America has recommended this goal for years, and on March, Representatives Brooks and Lipinski introduced House Congressional Resolution 37 for Congress to set a national goal to eliminate the trade deficit. It is only one sentence long: “Expressing the sense of Congress that Congress and the President should prioritize the reduction and elimination, over a reasonable period of time, of the overall trade deficit of the United States.”

As soon as the tax reform bill is signed by President Trump, Congress needs to pass this Resolution before the end of the year, so we can start 2018 on a new track.