From 1980 – 1999, China was granted Most Favored Nation status through presidential proclamation on an annual basis because the Trade Act of 1974 stated that “MFN status may not be conferred on a country with a nonmarket economy if that country maintains restrictive emigration policies” China was, and still is, a nonmarket economy and restricted emigration, but the Act allowed the president to “waive this prohibition on an annual basis if he certified that granting MFN status would promote freedom of emigration in that country.”

After the Tiananmen Square massacre in 1989, there was enough opposition to granting MFN status to China that the “House passed joint resolutions disapproving MFN for China in both 1991 and 1992,” but the Senate didn’t pass the joint resolution. Congress passed legislation in 1991 and 1992 that would have placed further conditions on China’s MFN status, but President Bush vetoed the legislation.

Prior to being elected, President Clinton announced he would link China’s MFN status to human rights progress beginning in 1994, but he reneged on his campaign promise and reversed himself: “On June 2, 1995, President Clinton transmitted to Congress his intention to waive the emigration prohibition and extend MFN status to the People’s Republic of China for an additional year, beginning July 3, 1995.”

The annual granting of MFN status to China by a presidential waiver continued through 1998. Note that “On July 22, 1998, legislation was enacted which replaced the term “most-favored-nation” in certain U.S. statutes with the term “normal trade relations.” This made it easier for Congress to make the fateful decision to extend “permanent normal trade relations,” or PNTR, to China when the Senate voted to give China permanent most-favored-nation status on September 19, 2000. This vote paved the way for China’s accession to the World Trade Organization.

This change in U.S. trade policy that eliminated potential tariff increases on Chinese imports resulted in American industries that were vulnerable to competing against lower Chinese prices experiencing greater employment loss, increased imports from China, and expanded share of the U.S. market by U.S. importers and Chinese exporters.

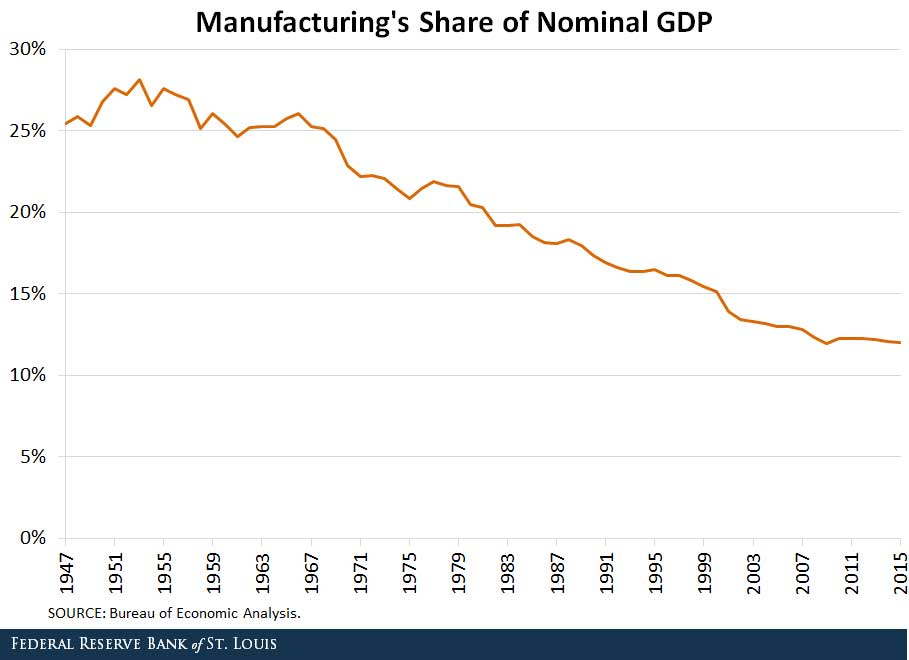

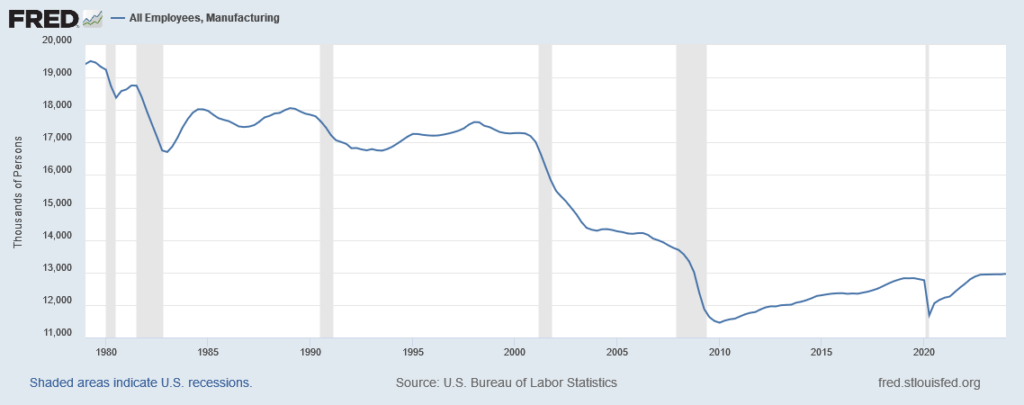

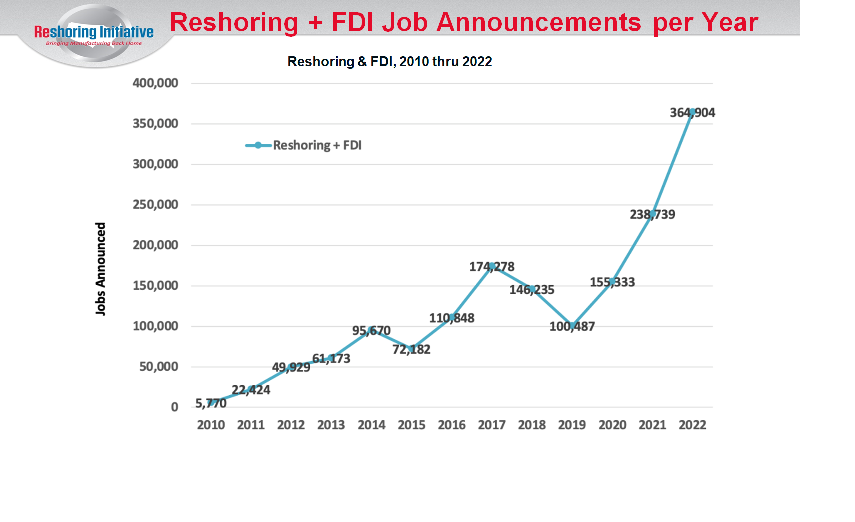

My three books and the hundreds of articles I’ve written since 2009 have described what has happened to U.S. manufacturing since 2001. Besides the loss of 5.8 million manufacturing jobs and the closure of an estimated 70,000 American manufacturers, American manufacturing shifted toward more high-tech, less labor-intensive production. However, as China upgraded their technology in the past few years, we started losing our high-tech manufacturing also.

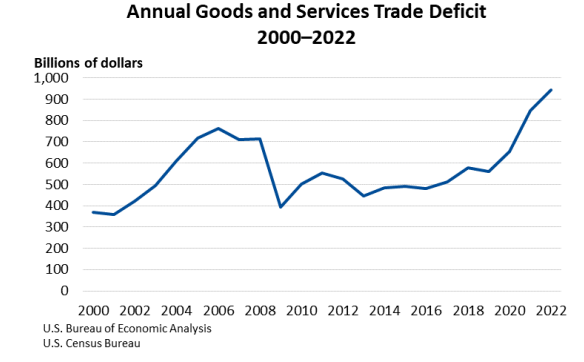

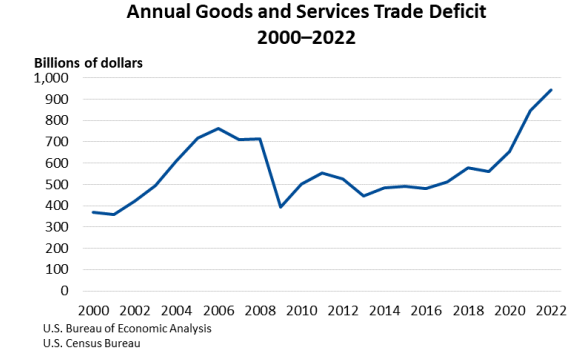

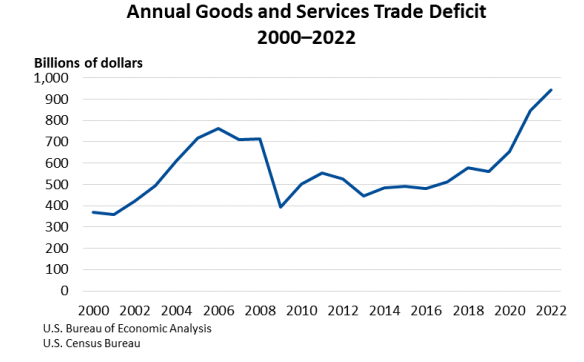

Our trade deficits increased every year from $381 Billion in the year 2000 to $945 Billion in 2022 as shown by the below chart.

During the 116th Congress (2019-2020), Senator Tom Cotton (R-Arkansas) introduced S. 4609, China Trade Relations Act, on September 17, 2020, that “would strip China of its permanent most-favored-nation status—also known as Permanent Normal Trade Relations…It would reinstate “extending most-favored-nation status to China an annual decision for Congress and the president.” Unfortunately, this bill didn’t get out of Committee for a vote.

In his press release, Senator Cotton said, “Twenty years ago this week, the Senate gave a gift to the Chinese Communist Party by granting it permanent most-favored-nation status. That disastrous decision made the Party richer, but cost millions of American jobs. It’s time to protect American workers and take back our leverage over Beijing by withdrawing China’s permanent trade status…Congress could override the president’s extension of MFN by passing a joint resolution of disapproval.”

In the 117th Congress (2021-2022), Senator Cotton reintroduced this bill on March 17, 2021 as S.785, the China Trade Relations Act of 2021, with Jim Inhofe (R-Oklahoma), and Rick Scott (R-Florida) as co-sponsors, but again, it never made it out of Committee for a vote.

This bill would have withdrawn “normal trade relations treatment from China and expands the bases of ineligibility for this treatment to include specified violations of human rights by China.

Specifically, during any period in which China engages in specified activities (e.g., using slave labor, performing forced abortion or sterilization, or hindering the free exercise of religion) (1) products from China shall not be eligible to receive nondiscriminatory treatment (normal trade relations), (2) China may not participate in any U.S. program that extends credits or credit guarantees or investment guarantees, and (3) the President may not conclude any commercial agreement with China.”

Jon Toomey, Senior Vice President, Government Relations for the Coalition for a Prosperous America, recently informed me that during the 118th Congress, “several bills have been introduced to revoke or modify China’s Most Favored Nation (MFN) status, also known as Permanent Normal Trade Relations (PNTR). Here are the key pieces of legislation:

S.125, China Trade Relations Act was introduced by Senators Tom Cotton (R-AR), Ted Budd (R-NC), Rick Scott (R-FL), and J.D. Vance (R-OH) on January 26, 2023. This bill would revoke China’s PNTR status and revert to the pre-2001 system where China’s MFN status must be renewed annually by the President. It also expands the Jackson-Vanik Amendment to include disqualifying factors such as human rights abuses and economic espionage.

S. 906, Ending Normal Trade Relations with China Act introduced by Senator Josh Hawley (R-MO).

This bill aims to withdraw China’s MFN status within two years of its enactment, allowing the President to impose tariffs on Chinese goods. It is designed to protect American workers and address issues related to China’s economic practices and human rights abuses.

H.R. 638, China Trade Relations Act of 2023 introduced by Representative Chris Smith (R-NJ). (House Companion bill to S.125 above) This bill mirrors the Senate’s China Trade Relations Act, aiming to revoke China’s PNTR status and impose similar human rights and trade-related conditions for MFN status renewal.

Jon said, “These legislative efforts reflect a significant shift in U.S. policy towards China, focusing on addressing concerns related to human rights violations, economic espionage, and the impact of China’s trade practices on American jobs and industries.”

In a press release, Senators Cotton, Budd, and Scott made the following comments:

Senator Cotton: China never deserved this privilege in the first place, and China certainly does not deserve it today. It’s time to protect American jobs and hold the Chinese Communist Party accountable for their forced labor camps and egregious human rights violations.”

Senator Scott: “There is no reason why the United States should be helping a communist government’s trade operation through preferential treatment and ‘most-favored-nation’ status. That is absolutely absurd when they are working against us. It is time to put American interests first, not the CCP, and reverse this antiquated law.”

Senator Budd: “The Chinese Communist Party is not America’s friend, and it is not a force for good in the world. From human rights abuses to the theft of U.S. jobs and intellectual property, the CCP must be held accountable.”

What would be the effect on tariffs from revoking China’s MFN/PNTR status? In the article titled, “Repealing China’s Most Favored Nation Status: A Guide,” Charles Benoit, Trade Counsel for the Coalition for a Prosperous America explained “Merchandise made in a country the U.S. awards MFN/NTR status is eligible for America’s extremely low, almost negligible ‘base’ tariffs. These are set out in Column 1 of the Harmonized Tariff Schedule of the United States (HTSUS)… The tariff rates in Column 1 match the tariff rates in the U.S. Schedule of Concessions to the WTO… Schedules of Concessions promise maximum tariff rates to every other WTO Member, with individual maximum rates fixed to a list of around 6,000 product categories, covering everything imaginable. So, what we promise to every WTO country, we implement in Column 1 of the HTSUS…Most U.S. MFN tariffs are set at 0%, and if you average the tariffs we do have, they come out at 3.4%, the lowest of any WTO Member.

Without PNTR status, all products from China would by default be subject to the higher tariff. This would reduce off-shoring by discouraging American investors and corporations from doing business in China. It would increase reshoring, and the diminishing demand for Chinese goods would bolster the sales of American manufactured products.

China’s strategic goal is to dominate the sectors of economic growth that historically have held the key to world power: transportation energy, information, and manufacturing. Their “Made in China 2025” plan is designed to dominate key technology sectors such as artificial intelligence, quantum computing, hypersonic missiles, and 5G. They also plan to become the dominant power in space by 2049.

Passing either of the Senate bills and the companion House bill would only be the first step to restoring our supply chains and ending critical economic dependencies on China.” It’s time for us to stop treating China as a friend and recognize China as the enemy to our national sovereignty that it is.