In January, the U. S. Business and Industry Council released a report, “Import Penetration Rises again in 2011; Challenges Manufacturing Renaissance, Insourcing Claims,” by Alan Tonelson. According to the report,” the share of U.S. markets for advanced manufactured goods controlled by imports reached another all-time high in 2011… and domestic manufacturing’s highest value sectors keep falling behind foreign-based rivals.”

The USBIC report shows that “imports captured 37.57 percent of the collective $2.01 trillion American market in 2011 for a group of more than 100 advanced manufactured products,” up from 37.07 percent in 2010. When government data to calculate import penetration rate were first issued in 1997,”imports controlled 24.49 percent of substantially the same group of U.S. manufactured products.”

“Fully 29 of the 106 sectors for which reliable data were available featured import penetration rates of 50 percent or more in 2011. In 2010, 31 of these industries had lost half of their home U.S. market to imports, and in 1997, only 8 of the 114 sectors initially studied were in this situation.”

Between 1997 and 2011, 98 industries lost shares of their home market while only 8 gained shares. The industries that gained shares are: “semiconductor machinery; saw mill products; paperboard mill products; motor vehicle stamping operations; transformer, inductor, and coil manufacturing; electron tubes; computer storage devices; and heavy duty trucks and chassis.”

The 98 industries include: “semiconductors; electro-medical apparatus; pharmaceuticals; turbines and turbine generator sets; construction equipment; farm machinery and equipment; mining machinery and equipment; several machine tool-related categories; and ball and roller bearings.”

The report states that “from 1997-2011, output fell in 38 of the 106 total industries studied over this time span – nearly 36 percent of the total. These ‘declining’ industries include electricity measuring and test instruments; relays and industrial controls; motors and generators; motor vehicle engines and engine parts; several machine tool-related categories; and environmental controls.” In 11 more sectors, output growth was less than 10 percent, “including semiconductors; semiconductor production equipment; motor vehicle transmission and power train equipment; miscellaneous industrial machinery; and medicinals and botanicals.”

Mr. Tonelson writes, “High and rising import penetration rates for this many critical domestic industries over nearly a decade and a half represent powerful evidence of chronic, significant weakness in domestic manufacturing.”

In a section titled, “The Manufacturing Renaissance that Isn’t, he disputes the predictions of the Boston Consulting Group’s 2011 report, “Made in America, Again: Why Manufacturing Will Return to the U.S.” This report contends that American manufacturing would experience a renaissance because of rising costs in China and other parts of Asia so there would be a convergence in the total costs of manufacturing by some regions of the U. S. by 2015.

If U. S. manufacturers are still losing market share to foreign competitors through import penetration in their home market, this is a sign that “the United States has not even started to become “increasingly attractive for the production of many goods sold to consumers in North America” as predicted by the Boston Consulting Group, much less experiencing a Manufacturing Renaissance.

What is even more troubling to Mr. Tonelson is that the USBIC report focuses on the capital-and technology-intensive sectors that are “keys to maintaining national prosperity, technological leadership, and national security.” The report shows that “dozens of America’s most advanced manufacturing industries are becoming just as vulnerable to import competition – and in some cases to import domination – as labor-intensive industries like clothing and toys.”

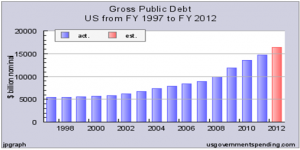

He concludes that the conventional stimulus strategies have had the disappointing results of “less growth and employment bang per investment-target stimulus buck with each passing year” because “U. S. imports of capital goods as such generates much less American output supported by much less American employment than purchases of domestically produced capital goods.”

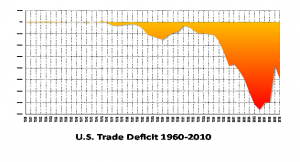

In his opinion, President’s Obama’s goal of doubling exports during the 2009-2014 period isn’t going to improve the situation either when imports keep rising faster than exports. While there was a 15.45 percent improvement from 2010 to 2011, the January-October 2012 period only showed a 4.56 percent improvement.

Mr. Tonelson points out that negotiating new trade agreements isn’t producing the desired effect of increasing exports. The latest agreement negotiated with Korea has had the opposite effect ? U. S. exports to Korea dropped by more than 18 percent while imports from Korea are up 4.74 from when it came into force in March 2012.

He concludes that the continued rise of import penetration in the U. S. indicates that American industry is losing ground relative to foreign-based competitors and “the nation is not making enough of the structural changes needed to create healthy growth and avoid reflating the last decade’s credit bubble.”

In an interview by Richard McCormack in the January 15, 2013 issue of Manufacturing & Technology News, Mr. Tonelson, stated, “I think the only way that these trends reverse meaningfully is if American trade policy changes. Unless we reduce the incentives of U.S. companies and companies all over the world to supply the U.S. market from overseas, this tide will not turn.”

While reducing the incentives of U. S. companies and foreign companies to supply the U. S. market from overseas is an important step in turning the tide, it would be the first of many steps we need to take. As I have written previously, we need to change our trade, tax, and regulations policies to help U. S. manufacturers be more competitive in both their home market and the global marketplace. We need to develop a national manufacturing strategy that would address all of the various factors that are resulting in the decline in the decline in the United States’ share of the global manufacturing output.

I did take exception to Mr. Tonelson’s dispute of the predictions of the Boston Consulting Group’s report and told him that the data is lagging reality ? “reshoring” is happening. As a manufacturers’ sales rep for American companies that perform fabrication services, I am in the “trenches” competing with offshore companies. Nearly every manufacturer I represent has experienced gaining new customers that are “reshoring” manufacturing from China. I have interviewed dozens of companies at trade shows over the past year and a half, and every company I interviewed had experienced “reshoring.” Nearly all of the San Diego region’s contract manufacturers of electronic manufacturing services have benefitted from “reshoring” in the past year.

The Reshoring Initiative, founded by Harry Moser in 2010, has documented case studies of companies reshoring. In the article, “Pumping Muscle into U.S. Manufacturing,” by Craig Barner in the March 6, 2013 issue of Forbes magazine, Mr. Moser said, “For example, about 220 to 250 organizations have brought manufacturing back to the U.S….with the heaviest migration from China. This represents about 50,000 jobs, which is 10% of job growth in manufacturing since January 2010, he said.”

“The top reshoring industries include electrical equipment, appliances and components; transportation equipment; and machinery, Moser said. Key reasons for returning to the U.S. include rising wages offshore, better quality of goods produced in the U.S., easier access to repairs and lower delivery costs, he said.”

On March 4, 2013, Prime Advantage, the leading buying consortium for midsized manufacturers, announced the findings of its eleventh semi-annual Group Outlook Survey. “A large majority — more than 70% of respondents — have increased their material and service purchases from American suppliers and service providers. Mexico is the second choice for sourcing, with nearly 28% of respondents moving sourcing to that region. The most frequently cited benefits that manufacturers hope to see in nearshoring are shorter lead times, as indicated by 67% of respondents, and lower inventories (49%). Among other benefits, companies cited better supply chain control (40%) and better overall communication (39%).”

If more American manufacturers would utilize the free Total Cost of Ownership Estimator™ developed by Harry Moser, more companies would understand the benefits of “reshoring” and foster a true renaissance in American manufacturing.