Now that the 119th Congress began less than two weeks ago, the priorities for Republican who have a slight majority in Congress on passing legislation that fulfills their campaign promise to support President’s Trump goal to Make America Great Again. To achieve this goal, Congress must pass legislation that helps rebuild American manufacturing.

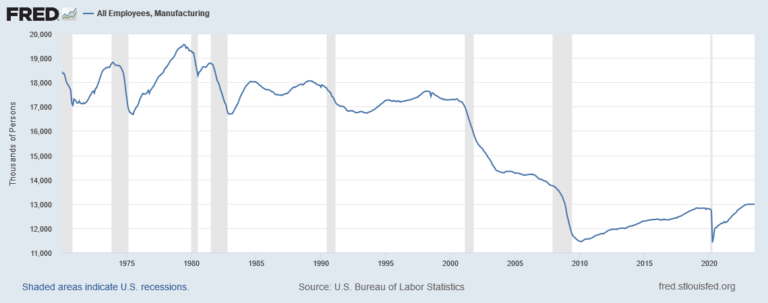

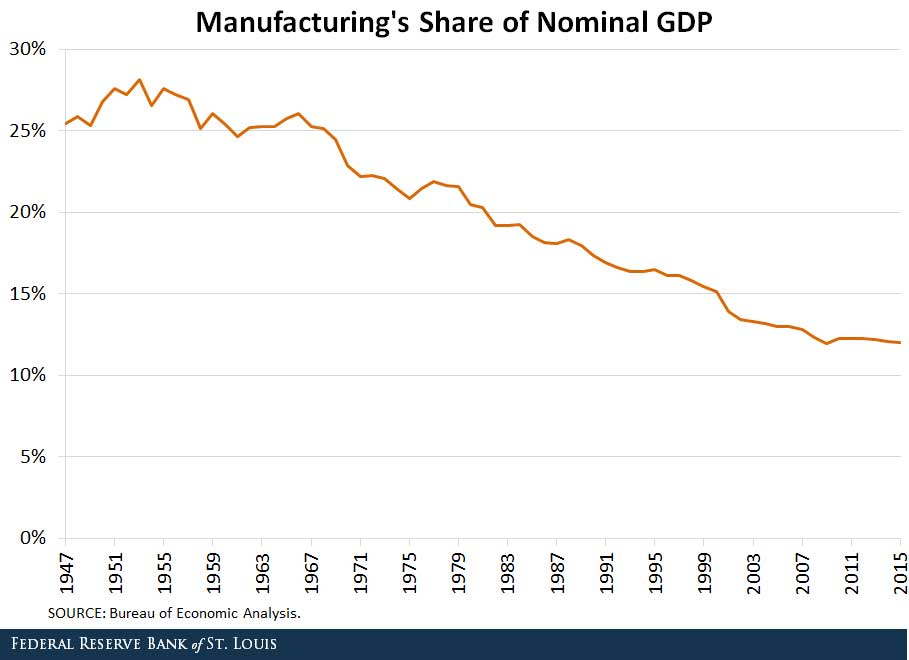

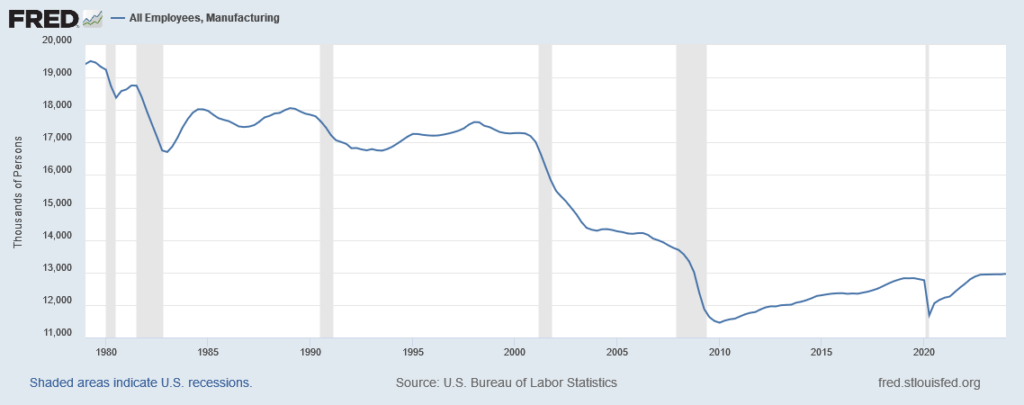

As a reminder of why this is critical, manufacturing is the foundation of the middle class because manufacturing jobs pay higher wages than most service and retail jobs, enabling more American to move into the middle class during the 1900s. Manufacturing employment was at an all-time peak of 19.6 million in June 1979, representing 22 percent of the labor force. The loss of millions of manufacturing jobs in this century has resulted in a shrinking middle class. The loss of these jobs also means a loss of tax revenue, increasing our national debt.

The domestic manufacture of innovative new technologies is what enabled the United States to become the leader of the free world. A secure domestic manufacturing supply chain is critical to maintaining our national sovereignty to remain a free country. We need to rebuild American manufacturing to create prosperity for our children and grandchildren.

Here are my suggestions for legislation that should be passed by Congress in order of importance:

Impose a Market Access Charge (MAC) as proposed by Dr. John R Hansen, (PhD economist and Economic Advisor, The World Bank (retd.) “forcing foreigners to pay a market access charge (MAC) if they want to dump their speculative money into America’s financial markets when US trade deficits show that the global demand for dollars and dollar-based assets like stocks and bonds is already excessive. In addition to encouraging the dollar to move to a more competitive level, thus boosting economic growth and family incomes, the MAC could also generate hundreds of billion dollars of new government revenue per year.

The MAC would start low, rise gradually until foreign demand for dollars was consistent with balanced trade, and thereafter be adjusted periodically to maintain balanced trade. The MAC charge, which is fully legal under US and international law… Even a very low rate of say 1.5 percent, the MAC, which would be paid entirely by foreign speculators, not Americans, could generate over $1 trillion dollars of new revenue per year. This could gradually be used to eliminate the U.S. deficit…and to start paying down America’s total internal and external debts.

John emailed me this comment: “We should regard the MAC as a tariff on the import of foreign money — just as regular tariffs are a tax on the import of foreign goods. A MAC tariff would create millions of new, well-paying jobs and would give the U.S. Government billons of additional revenues, all paid out of the pockets of foreigners, that could be used to:

- increase the quality and adequacy of government services for all Americans.

- reduce the burden of taxes paid by Americans.

Note that, unlike traditional tariffs on imports which increase U.S. prices, especially in the short term, the MAC would be paid entirely by foreigners. Furthermore, unlike tariffs that only restrict imports (by making them more expensive for Americans), the MAC would also stimulate exports and American jobs by making made-in-America products more competitive in foreign markets.

The American jobs that the MAC would create would emerge not only in crowded urban areas, but also in the poverty-stricken regions of America where, as President Trump mentioned in his 2017 inaugural address, “rusted-out factories are scattered like tombstones across the landscape of our nation,” especially affecting the poor workers who lost their jobs due to the China Shock.

Likewise, by making grown-in-America food and other agricultural products more competitive with competing foreign goods, the MAC would help reverse the sharp deterioration of family incomes on American farms and ranches.

Finally, passing legislation for the MAC would also help America reduce its mountain of government debt — debt that threatens the stability of our country today and the quality of life for our children tomorrow.”

Pass a Patent Reform Bill to restore inventors’ rights and end abuses by the Patent Trial and Appeal Board (PTAB).

The largest inventors’ organization, US Inventors, supported the passage of the following bill in the last session of Congress: HR 8134, the Restoring America’s Leadership in Innovation Act (RALIA), introduced by Rep. Thomas Massie (R-KY) and Rep. Marcy Kaptur (D-OH).

RALIA sought to revitalize patent protection by restoring injunctive relief, eliminating confusing judicially created eligibility tests, and abolishing the Patent Trial and Appeal Board (PTAB). RALIA would have reversed the effects of several Supreme Court decisions and of the America Invents Act, largely repairing most of the erosion of US patent rights accumulated over the last several decades. US Inventors urges Congress to pass the reintroduction of this bill in this session of Congress.

It would be nice for the USPTO to get refocused on its mission to ensure that the intellectual property system contributes to a strong global economy, encourages investment in innovation, and fosters an entrepreneurial spirit.

Revoke China’s Most Favored Nation Status (aka Permanent Normal Trade Relations (PNTR)

After President Clinton granted China Most Favored Nation Status annually from 1995 on, the U.S.Senate voted to give China permanent most-favored-nation status on September 19, 2000, and on October 10th, 2000, President Clinton signed into law the U.S.-China Relations Act of 2000. This paved the way for China’s accession to the World Trade Organization. This started the trend of American manufacturers moving manufacturing to Chinese vendors and the huge influx of imported good from China flooding the U.S. when tariffs were drastically reduced.

Our trade deficit with China increased every year from $83.8 Billion in the year 2000 to $279.1 Billion in 2023 (projected to be about the same for 2024). This was down from a peak trade deficit with China in 2018 of $418.2 Billion.

In my article, “We must Revoke China’s Most Favored Nation Status, I wrote that during the 118th Congress, “several bills have been introduced to revoke or modify China’s Most Favored Nation (MFN) status, also known as Permanent Normal Trade Relations (PNTR)” but none of the bills were passed out of Committee to be voted on by the House or Senate.

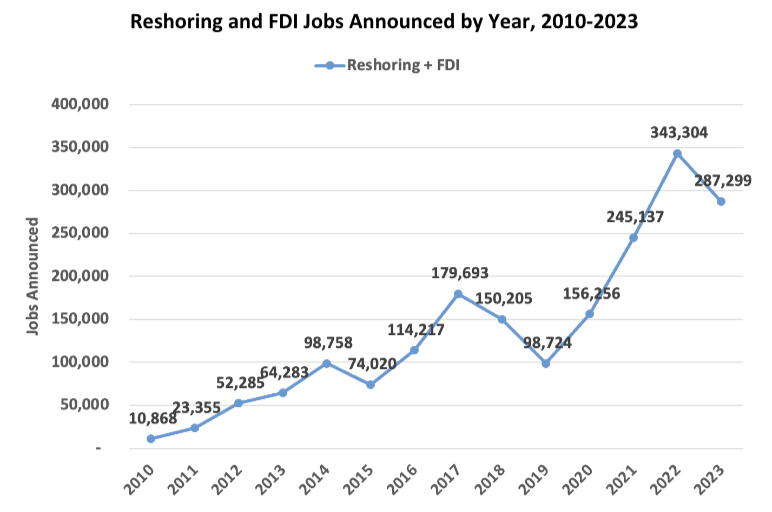

Passing such a bill should be a major priority for the 119th Congress as soon as possible. Without PNTR status, all products from China would by default be subject to higher tariffs. This would reduce off-shoring by discouraging American investors and corporations from doing business in China. It would increase reshoring and diminish demand for Chinese goods, bolstering the sales of American manufactured products.

Reduce the Allowed Value of De Minimis imports

De Minimis imports was codified in Section 321 of the Tariff Act of 1930 as an administrative exemption for imports under $1. However, the Trade Facilitation and Trade Enforcement Act of 2015, signed by President Barack Obama Feb. 24, 2016, “ raised the value of a shipment of merchandise imported by one person on one day that generally may be imported free of duties and taxes from $200 to $800.

This allows foreign vendors, such as Temu, Shein, and Amazon vendors, to ship directly into the United States. When a package receives de minimis treatment, it arrives without the need of a customs broker or bond, without paying any tariffs or taxes, and without meaningful possibility of regulatory oversight.

The Coalition for a Prosperous America states: “U.S. companies and workers are subjected to a new level of job-destroying competition. Illicit drugs, such as fentanyl, and counterfeit goods are shipped directly to US consumers while evading detection. The predictable result is a major calamity putting U.S. producers and traditional retailers out of business and destroying jobs.” CPA urges “Congress to lower the de minimis threshold to $9 among other reforms.”

Reauthorize a Reformed Tax Cuts and Jobs Act (TCJA)

Major provisions of the Tax Cuts and Jobs Act of 2017 will expire by the end of 2025, so American families and business could experience dramatic increases in taxes in 2026.

Since manufacturers require affordable taxes to succeed and grow, reform and reauthorization of TCJA is imperative.

The Tax Foundation recommends that Congress “prioritize provisions that have the largest “bang for the buck,” or the most economic growth per dollar of revenue loss. These include immediate cost recovery for investments in the types of machinery and equipment upon which millions of small and large businesses depend, as well as immediate write-offs for investments in research and development. These two policy changes support a growing economy like no other tax policies proposed since the corporate tax rate was reduced from 35 percent to 21 percent.”

While the reduction in corporate taxes was a big benefit to large corporations, it was actually a tax increase from 15% to 21% for small business and small manufacturers. The fabrication companies I represent as a sales rep all saw this increase in their corporate taxes because they generated revenues under $10 million a year.

President Trumps’s proposal for a 15% corporate tax rate should be seriously considered. Read the Cato Institute’s “The Case for Trump’s 15 Percent Corporate Tax Rate” here.

Pass Legislation to Address China’s Exploitation of U.S. Capital Markets, Economic Incentives, and Trade Policy

Several bills to address the problem of China’s exploitation of U.S. capital markets were introduced in the 118th Congress, but none of them were passed out of committee to be voted on by the House or Senate. For a full list of this legislative package, go to this link of the website of the Coalition for a Prosperous America (CPA) as there is insufficient space in this article to describe all of these bills. All of these bills will have to be introduced in the 119th Congress. As a long-time member of CPA, I join them in urging Congress to pass a legislative package that will “prohibit U.S. capital, economic incentives, and trade preferences from benefitting China and other adversarial nations.”

Passage of the legislation mentioned in this article would help stop the destruction of American industry and innovation, the loss of high-paying manufacturing jobs, and the collapse of communities. It would d be a big help in rebuilding American manufacturing’s capacity and eliminate dependence on China and other adversarial nations. It would especially help rebuild manufacturing capacity in industries that are critical to U.S. economic and national security. It would help to create prosperity for our children and grandchildren and ensure that they will continue to live in a free country.